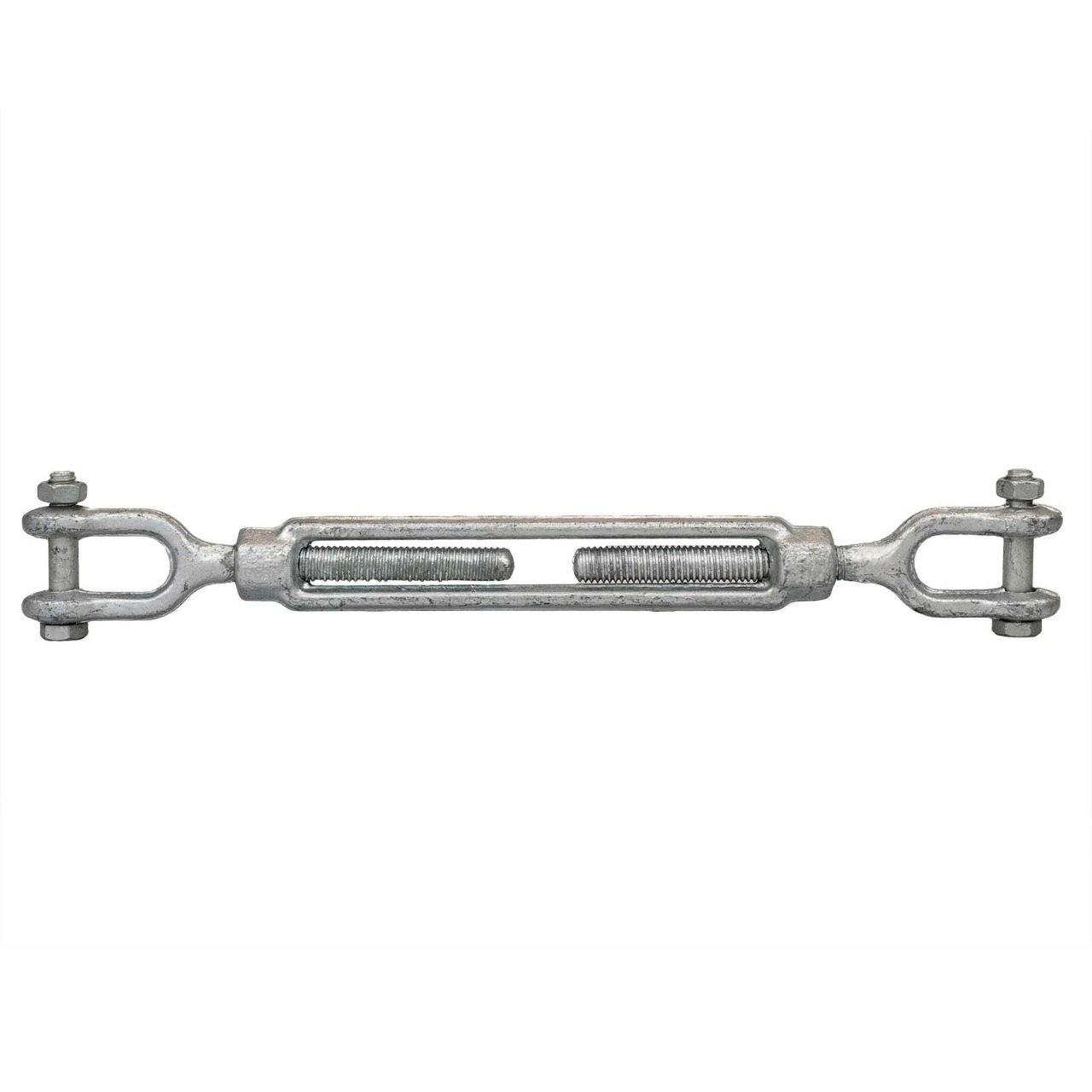

Jaw & Jaw Turnbuckles

Precision Tensioning for Structural and Rigging Applications

Jaw & Jaw Turnbuckles are adjustable fastening devices used to tension, tighten, and adjust the length of ropes, cables, rods, or tie rods in various industrial, marine, and construction applications. Featuring two jaw-end fittings (also known as clevis ends), these turnbuckles provide secure and removable connections ideal for heavy-duty tensioning tasks.

Heavy-Duty Construction: Made from forged steel or stainless steel for superior load-bearing capacity.

Dual Jaw Ends: Equipped with clevis pins and cotter pins for easy installation and secure locking.

Corrosion Resistance: Available in galvanized and stainless steel (SS304 / SS316) variants for long-lasting outdoor performance.

Precision Threading: Smooth adjustment for fine-tuning tension and alignment.

Multiple Sizes: Offered in standard dimensions suitable for various industrial and marine uses.

Specification | Details |

|---|---|

Type | Jaw & Jaw Turnbuckle |

Material | Carbon Steel / Galvanized Iron / SS304 / SS316 |

Finish | Hot-Dip Galvanized / Electro-Galvanized / Polished |

Size Range | M6 – M36 or Custom Sizes Available |

Thread Type | Metric or UNC Thread |

Working Load Limit (WLL) | Up to 12 Tons (depending on size & material) |

Standards | ASTM / DIN / BS / EN Compliant |

End Fittings | Forged Jaw Ends with Clevis & Cotter Pin |

Structural tensioning in steel frameworks

Cable bracing and suspension systems

Marine and rigging operations

Fencing, barrier, and load-securing systems

Shade structures, masts, and signboard installations

✅ Smooth & Accurate Adjustment – Ideal for precise alignment and cable tensioning

✅ High Load Capacity – Engineered for heavy-duty lifting and structural applications

✅ Weather & Corrosion Resistant – Perfect for marine and outdoor environments

✅ Custom Sizes & Finishes Available – Tailored to meet your project specifications

✅ Certified Quality – Manufactured under strict quality standards

Q: What is the difference between Jaw & Jaw and Eye & Eye turnbuckles?

A: Jaw & Jaw turnbuckles have clevis ends for quick detachment, while Eye & Eye models are suited for permanent installations.

Q: Can these turnbuckles be used outdoors or in marine environments?

A: Yes, especially stainless steel (SS316) versions, which resist corrosion and saltwater damage.

Q: Do you supply custom sizes or thread combinations?

A: Yes, we offer custom manufacturing upon request.

🔧 Comprehensive Range – From M6 to M36, in galvanized and stainless steel

🌍 Supplying Across UAE – Quick delivery to Dubai, Sharjah, Abu Dhabi, and beyond

🧰 Technical Expertise – Guidance on load ratings and correct installation

🏢 Trusted Industrial Partner – Serving construction, marine, and oil & gas sectors